Reactive HE Dyes

Product Details:

- Solubility Soluble in water

- HS Code 32041600

- Size Standard packaging: 25kg bags/drums

- Application Textile Industry

- Solvent Color Clear solution when dissolved in water

- Shelf Life 2 years (when stored properly)

- Ph Level 6 – 7 (1% soln)

Reactive HE Dyes Product Specifications

- High

- Solid – Powder/Granular/Paste

- Powder, Granular, or Paste

- Varies per dye (commonly not assigned for mixtures)

- Odorless

- Varies based on color

- Non-Poisonous

- Odorless

- High Exhaust Dyes, HE Dyes

- Reactive Dye

- 1.5 Gram per cubic centimeter(g/cm3)

- Not applicable (decomposes)

- Max 2.0

- Varies

- 99% Min.

- Very Good

- Standardized up to 100%

- >200°C (typically decomposes before melting)

- Excellent washing, light, and perspiration fastness

- Varies per dye, typically 12225-82-4, etc.

- Industrial Grade

- Standard packaging: 25kg bags/drums

- 32041600

- Soluble in water

- 6 – 7 (1% soln)

- Used for coloring textiles, especially cellulose fibers (cotton, viscose), also blends of polyester/cotton

- Clear solution when dissolved in water

- 2 years (when stored properly)

- Textile Industry

- Anionic

- Bags, Jumbo Bags, HDPE Drums, Custom Packaging

- Keep in a cool, dry place away from direct sunlight

- Using alkali and salt

- 80°C - 85°C (High temperature application)

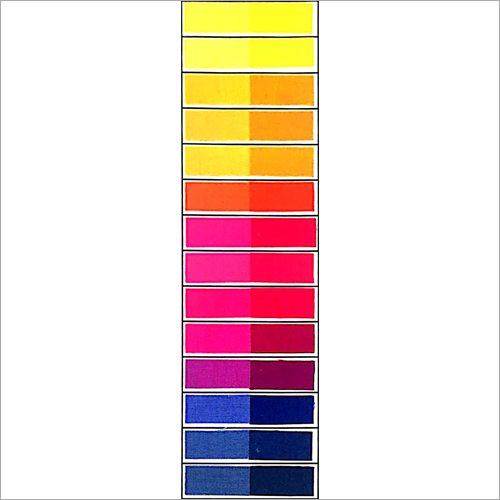

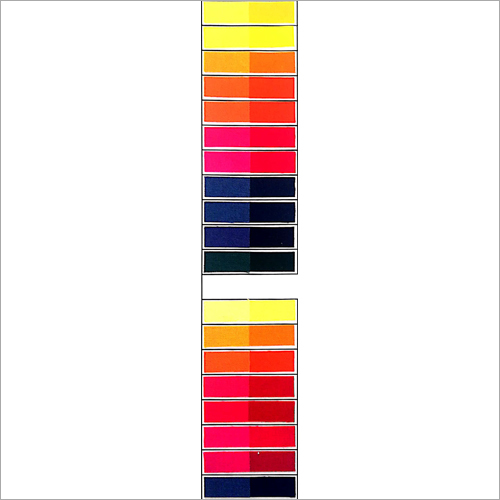

- Available in Yellow, Red, Blue, Navy, Black, Orange, Green, and other shades

- High Exhaust (Long liquor dyeing for even coloration)

- Compatible with all standard auxiliaries

Reactive HE Dyes Trade Information

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Reactive HE Dyesare specially produced for the purpose of exhaust dyeing under long liquor proportions. These kinds of dyes are less sensitive to time & temperature, and glauber salt concentration. Level and fastness characteristics are better than M brand reactive when compared. These are suitable for dyeing knitwear as well as cellulosic component of cellulosic / polyester blended cloths. Processed by expert professionals with approved methods using needed compounds,Reactive HE Dyesare available in many different desired colors with safe packaging.

Product Specification :

|

Direct Dyes (Non Benzidine) |

Solubility at 50oC (gms/lit) |

Fastness to |

|||

|

Light 1/1 |

Washing |

Hypochlorite |

Perspiration |

||

|

Yellow HE4G |

70 |

55 |

5 |

1-2 |

4 |

|

Yellow HE6G |

70 |

5 |

5 |

1-2 |

4-5 |

|

Golden Yellow HER |

80 |

5 |

5 |

2-3 |

4-5 |

|

Orange HER |

50 |

4-5 |

4-5 |

3 |

3-4 |

|

Orange HE2R |

50 |

4 |

4 |

3 |

3-4 |

|

Red HE7B |

100 |

4-5 |

4-5 |

3-4 |

4-5 |

|

Red HE8B |

100 |

4-5 |

4-5 |

3-4 |

4-5 |

|

Blue HERD |

90 |

5 |

4-5 |

1 |

5 |

|

Navy Blue HER |

70 |

5 |

3-4 |

3-4 |

4-5 |

|

Navy Blue HE2R |

70 |

4 |

2-3 |

2-2 |

4 |

|

Green HE4BD |

100 |

4-5 |

2-5 |

2 |

4-5 |

Versatile Color Options for Textile Needs

Reactive HE Dyes are available in a comprehensive spectrum, from vibrant yellows and reds to deep blues and blacks. This wide selection allows textile manufacturers and dyers to achieve precise, consistent shades for an array of fabric styles. Custom blending further expands the color possibilities, meeting the diverse demands of global markets.

Efficient High Exhaust Dyeing Process

Designed specifically for long-liquor, high-exhaust applications, these dyes maximize uptake and produce uniform coloration on cellulose fibers such as cotton and viscose. The recommended dyeing temperature of 8085C, along with alkali and salt fixation, ensures deep penetration and lasting colorfastness, optimizing both small and large-scale production.

Consistent Quality and Reliable Performance

Manufactured and standardized with a minimum purity of 99%, Reactive HE Dyes provide superior wash, light, and rubbing fastness. This reliability is critical in the textile industry, where durability alongside color brilliance determines product appeal. Their high compatibility with standard dyeing auxiliaries further streamlines production processes.